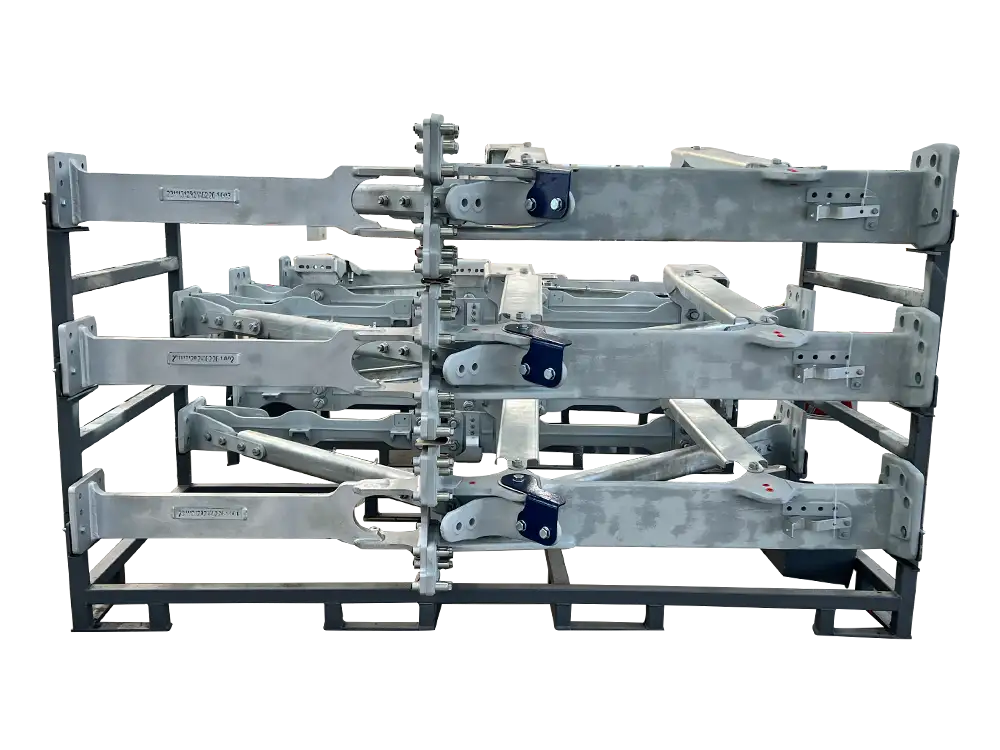

3MW Generator Foundation Frame

- Commodity name: 3MW Generator Foundation Frame

- Description

-

Production Capacity

Advanced equipment ensures that all processes, from material cutting, assembly, welding, machining, to blasting and painting, are at the forefront of global technology.

● Laser Cutting Machines: 4.5m x 18m machines from Tanaka (Japan)

● Cranes: 50-ton and 80-ton cranes from GH (Spain)

● Floor-Type Boring and Milling Centers: A 4.1m x 12m (Spain)

● Welding Equipment: EWM welders (German) and Welding Robots from Yaskawa (Japan)

Quality Assurance

We have obtained multiple system qualifications:

● IS09001 Quality Management System Certificate

● IS014001 Environmental Management System Certificate

● ISO3834 Quality Requirement for Fusion Welding of Metallic Materials

● ASME U/S Boiler and Pressure Vessel Certificate and Code

● DIN EN 1090-1/2 Execution of Steel Structures

● CWB 47.1 CWB Certification for Fusion Welding of Steel

3MW Generator Foundation Frame is a key support structure designed for 3MW generators.

1. Structural Design

High-strength Materials

3MW Generator Foundation Frame uses high-quality metal materials such as high-strength steel. This material has excellent compression, bending and torsion resistance, and can withstand the huge weight and various complex forces generated by the 3MW generator during operation. Ensure that the generator remains stable during long-term operation and avoid the deformation of the foundation frame affecting the normal operation of the generator.

Accurate Size and Layout

The size of the frame is accurately calculated and designed. The layout of each part is reasonable to meet the installation requirements of each component of the generator. For example, providing precise positioning points for key components such as the stator and rotor of the generator to ensure that their relative positions are accurate, which is crucial for the optimization of the electromagnetic and mechanical properties of the generator.

2. Functional Features

Stability Guarantee

It provides solid support for the 3MW generator and effectively isolates external vibration and interference. When the generator rotates at high speed and generates vibration, the foundation frame can absorb and disperse the vibration energy, preventing the vibration from being transmitted to the surrounding equipment and building structures, thereby ensuring the stability and safety of the entire power generation system.

Strong durability

Due to the use of high-quality materials and advanced anti-corrosion treatment technology, the foundation frame has strong durability. It can work for a long time in various harsh environmental conditions, such as humidity, high temperature, high salt fog and other environments, greatly reducing maintenance costs and extending the service life of the entire power generation system.

Good compatibility

The 3MW Generator Foundation Frame is designed with compatibility with other related equipment in mind. It can be easily connected and coordinated with generator accessories such as cooling systems and control systems, providing convenience for the integration of the entire 3MW power generation system.

With its excellent structural design and functional characteristics, the 3MW Generator Foundation Frame is an important guarantee for the reliable operation of the 3MW power generation system.

FAQ

We mainly involve various types of metal structural products such as frames, beams, plinths, housings, pressure vessels, pressure pipelines etc., which can meet the needs of customers in different fields.

Our main customers cover wind power, construction machinery, marine industry, electrical power, transportation equipment, and other fields. In addition to domestic customers, our products are exported to Europe, America, Asia, and other global countries and regions, and we have established long-term and stable cooperative relationships with many well-known domestic and foreign enterprises.

Our company has many years of production experience and a professional technical team in metal welded structural parts. We adopt advanced welding processes and equipment to ensure the welding quality and strength of products. At the same time, we are constantly committed to technological innovation to meet the ever - changing needs of the market.

We can provide customized services from design to production according to the specific needs of customers. Whether it is the size, material, or performance requirements of the product, we can provide satisfactory solutions for customers.

We have established a strict quality management system and strictly control the quality in all aspects, from raw material procurement, production and processing to final product inspection. We use advanced testing equipment to comprehensively test the appearance, dimensions, performance, etc. of products to ensure the products meet international standards and customer requirements, including but not limited to ISO 9001 quality management system standards, EN 15085 welding quality standards, ASME pressure vessel standards, etc. We regularly calibrate and maintain testing equipment to ensure the accuracy and reliability of the test results.

We have an excellent production planning and scheduling system. According to the order requirements and product characteristics of customers, we can reasonably arrange the production progress to ensure that products can be delivered on time.

Need Assistance? We're Here To Help!

To request a quotation or locate your local distributor, please fill out the form below.lf you cannot find the product you need.

feel free to contact us at +865328522 5888 or contact@beckmann-volmer.cn, and we will respond to you within 1 hour.

More Products